Sustainability

Lemnos Sustainability 11

Edge Clock – Preserving Traditional Techniques and Exploring New Materials

An Aluminum Wall Clock Crafted with Advanced Sand Casting Techniques from Takaoka, Toyama

Preserving 400 Years of Traditional Craftsmanship While Exploring New Materials

Takata Foundry began as a personal business specializing in Buddhist altar fittings using brass casting, a traditional industry in Takaoka City. Over time, it has gained recognition as a factory with exceptional casting expertise. However, as the role of Buddhist altar fittings has changed over time, demand has gradually declined, making it essential to explore new materials and products. In 2000, while carrying forward 400 years of traditional craftsmanship, we sought to develop products suited to modern interiors. Collaborating with the London-based design unit AZUMI, we developed a wall clock using aluminum sand casting techniques. It uses the aluminum alloy AC7A, a high-quality material known for its excellent corrosion resistance and beautiful polished luster. However, its poor fluidity makes the casting process particularly challenging. The simple, sharp design leaves no room for imperfections, demanding a high level of craftsmanship. At the same time, this challenge ignites the passion of the on-site craftsmen. Driven by the enthusiasm and dedication of both designers and artisans, we aimed to make the Edge Clock a truly one-of-a-kind aluminum sand-cast clock.

TAKATAFACTORY

TAKATAFACTORY

A Design That Seamlessly Integrates Material, Processing, and Form

The early 2000s, when this clock was developed, coincided with the rise in recognition of the Lemnos clock brand. While it was experiencing steady growth, there was still room for further development in its core aluminum casting products, reflecting its origins. Before starting the design process, the designer visited Takata Foundry, an aluminum sand casting factory, where he witnessed a world-class, highly refined manufacturing environment. This experience led him to center the design around maximizing the potential of the foundry’s technical assets. The result is a design that explores the seamless relationship between material, processing, and form. By daring to incorporate details that are typically challenging in sand casting—such as a large, smooth cast surface and deep, delicate engravings following from the outer rim to the hour markers—this clock achieves a new form of expression, backed by exceptional craftsmanship. Designed to hold its presence even against textured walls like brick or concrete, this clock offers a unique, artisanal quality that cannot be found elsewhere.

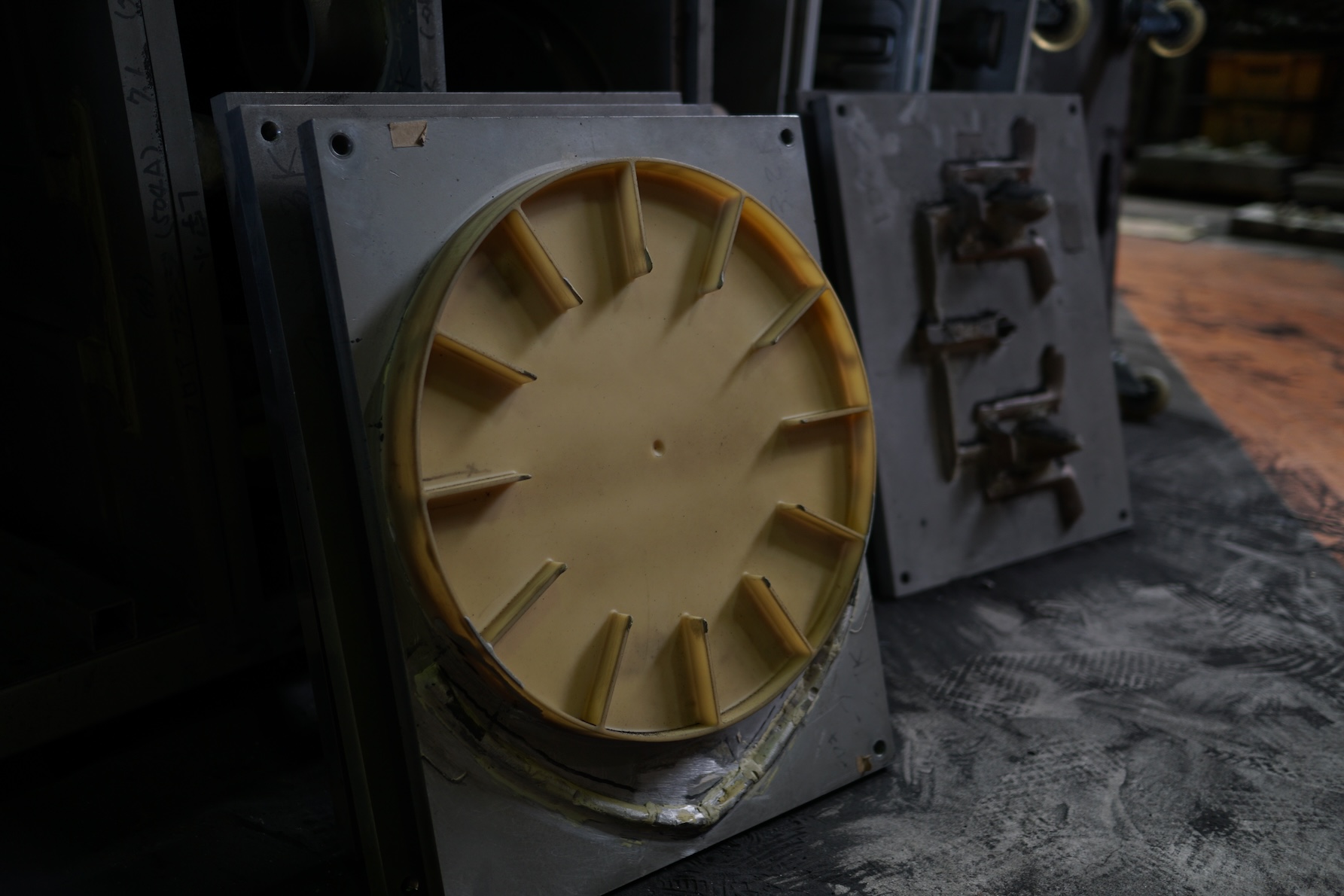

Bottom part of the sand mold placed inside the casting frame

Bottom part of the sand mold placed inside the casting frame

Pouring molten metal into the mold

Breaking the sand mold to extract the casting

A Contemporary Wall Clock with the Texture and Refinement of a Handicraft

While many simple-looking wall clocks exist, finding one backed by such advanced sand casting techniques is extremely rare. It features a large, smooth cast surface, deep and delicate engravings following from the outer rim to the hour markers, polished edges, and a contrast between the brushed and sandblasted surfaces. All of these elements are a testament to exceptional craftsmanship. A wall clock that embodies the texture and refinement of a handicraft remains a rarity in the market. This clock has pioneered its own niche within contemporary wall clock design. The exceptional level of craftsmanship has, in turn, made it impossible to create perfect imitations, reinforcing its uniqueness. The clock’s refined texture ensures that even when placed against highly textured walls such as brick, it retains a strong presence—an uncommon quality that sets it apart from other products. Its international popularity is a testament to its uniqueness and refined aesthetic.

Polishing process

The Vision of Creating a One-of-a-kind Aluminum Sand-cast Clock

Since its launch in 2002, the Edge Clock has maintained its original style for over 20 years. While it took time for its distinctive design to gain acceptance, it attracted attention after being featured in the “Shin Azumi RECENT WORKS” exhibition at SEMPRE Aoyama in 2005. This exposure led to sales at many design shops across Japan and even at the Museum of Modern Art (MoMA) in New York. As a result, annual sales doubled, and the clock was further recognized by being selected for the JIDA Design Museum Collection and the Matsuya Design Collection. It has been highly acclaimed as a beautifully crafted product that maximizes the potential of local craftsmanship through thoughtful design.

Today, with an expanded range of sizes, the clock is widely used, not only for personal spaces, but also in commercial facilities and offices. Its presence in a wide range of locations speaks to its broad appeal. With over 18,000 units sold, the Edge Clock has successfully realized its initial vision: a truly one-of-a-kind clock that cannot be easily replicated and continues to be cherished by many.

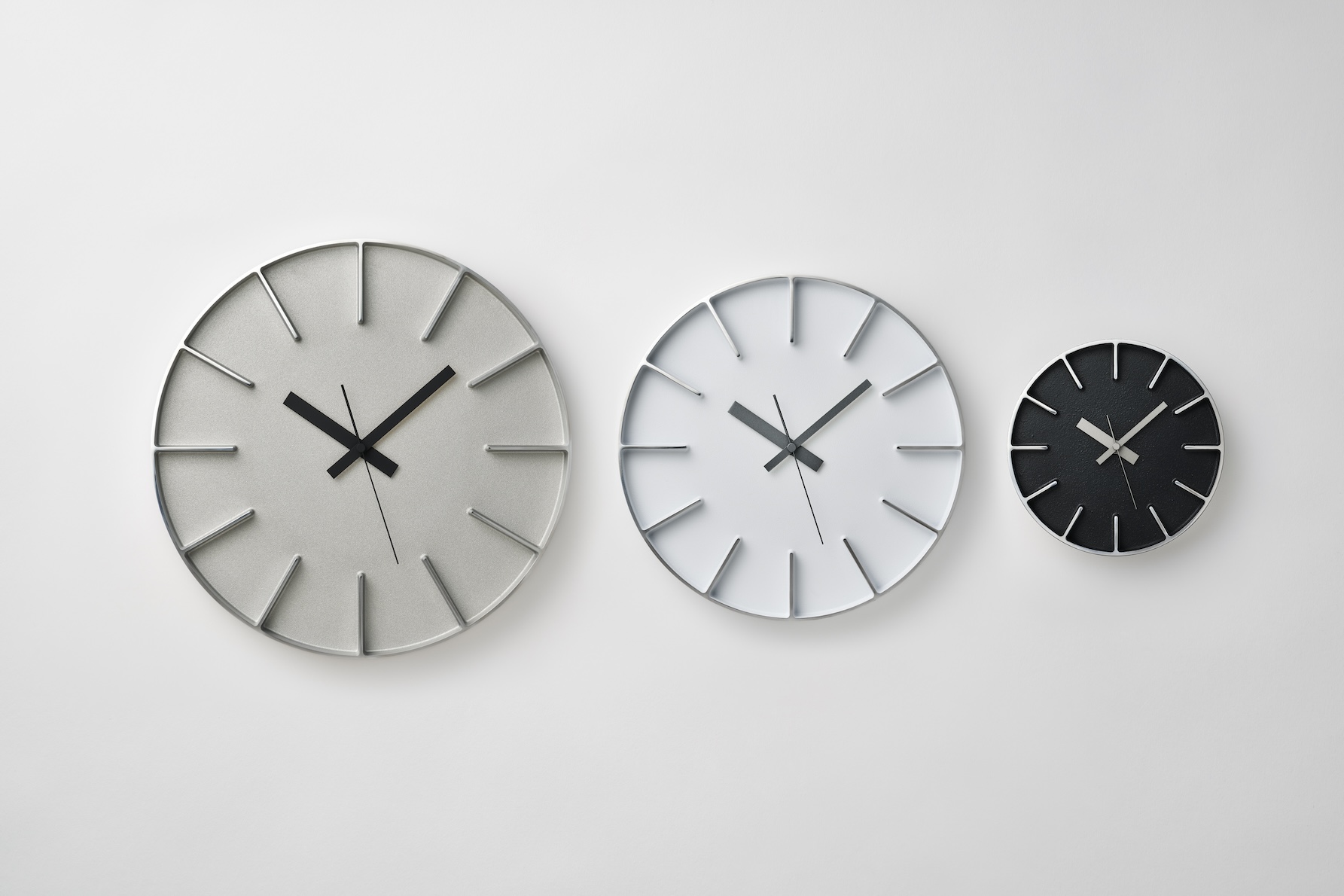

Left:AZ-0115 SL(φ350)、AZ24-08 WH(φ290)、AZ-0116 BK(φ180)

Left:AZ-0115 SL(φ350)、AZ24-08 WH(φ290)、AZ-0116 BK(φ180)