Sustainability

Lemnos Sustainability 04

Maximizing Material Use – Efforts to Eliminate Waste

Since its debut in 2012, the ‘MIKI’ clock designed by Yuichi Nara has been cherished by many for its long-life design. The clock frame is crafted from zelkova wood, a material that is highly valued for its beautiful grain and exceptional durability. This premium domestic wood is traditionally favored for high-end furniture and temple architecture. The ‘MIKI’ clock showcases a luxurious design, featuring a seamless frame carved from thick zelkova logs and shaped into a circle using a lathe.

Product: MIKI/Natural (NY12-06 NT)

Product: MIKI/Natural (NY12-06 NT)

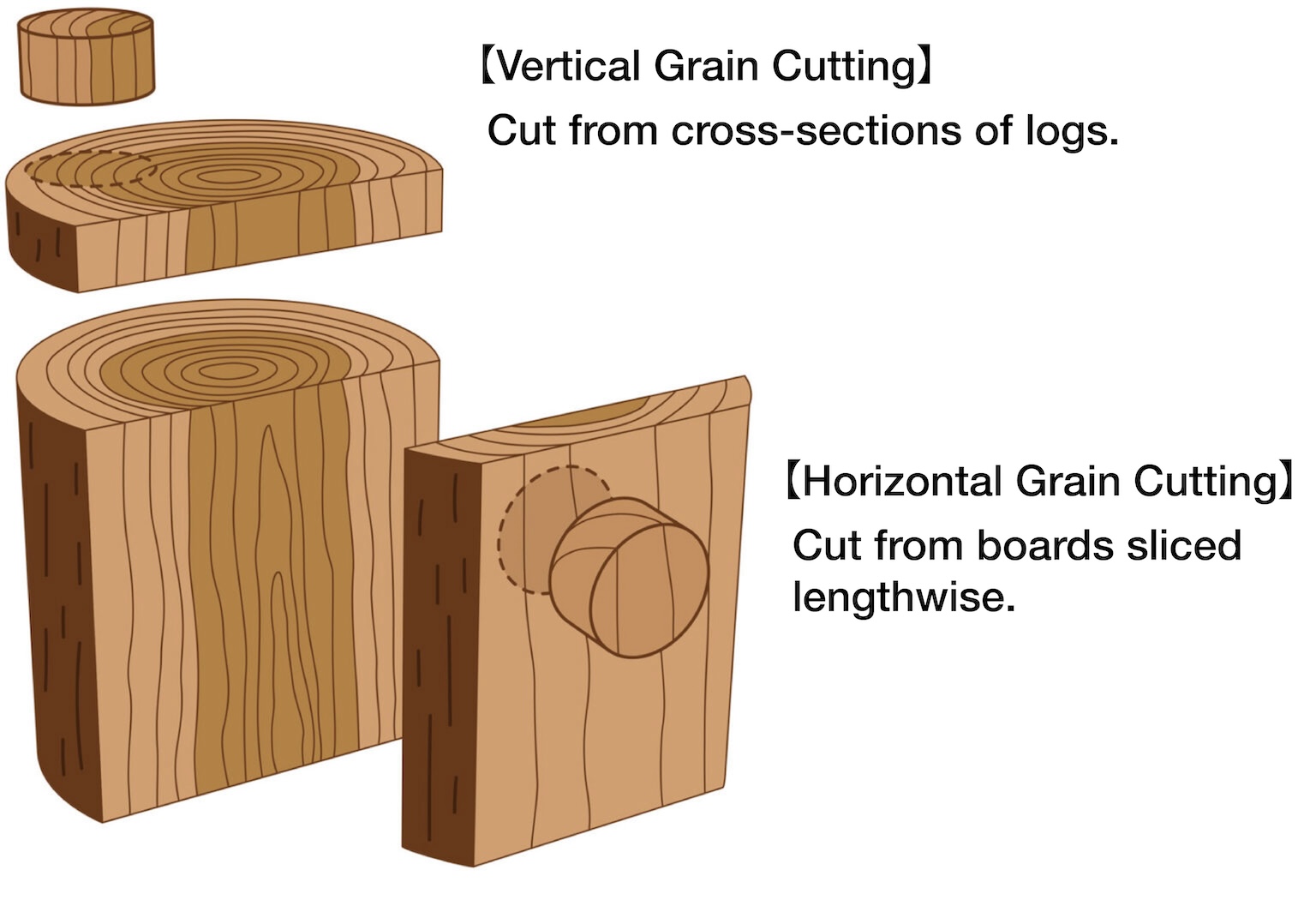

“Shogawa in Toyama Prefecture, where the zelkova frames are produced, is one of Japan’s most renowned regions for turned wood materials. Its defining characteristic is the use of cross-grain processing to highlight the beauty of the wood grain patterns (mokume) that appear along the circumference of the clock frame when the wood is turned. Cross-grain processing involves slicing logs lengthwise to extract the wood, with the wood’s natural water pathways running parallel to the front face of the clock frame. This alignment causes the annual rings to appear in various shapes, creating a diverse range of patterns and expressions on the final product.

Two Types of Woodcutting Methods: Shogawa specializes in horizontal grain cutting.

Processing scene of the NY12-06 frames

Occasionally, beautiful grain patterns may include knots (brownish spots), and their size cannot be determined until the wood is processed. Due to their condition, some pieces were unsuitable for use in products and, as a result, had to be discarded. However, we always strived to avoid discarding any frames, no matter how small in number, that had been carefully crafted by skilled woodturners. Our goal was to make use of every possible frame. In 2022, the ‘MIKI SUKI URUSHI’ and ‘MIKI URUSHI WAJIMA’ clocks were born from a collaboration between designer Yuichi Nara and lacquer craftsmen from Wajima City in Ishikawa Prefecture. This collaboration between regions helped eliminate waste by transforming discarded frames into lacquer-coated products.

Products: MIKI SUKI URUSHI (NY22-03), MIKI URUSHI WAJIMA/Red (NY22-04 RE), Black (NY22-04 BK)

Lacquer processing scene : Frames (lined up on the right) have an undercoat and are coated with a thin, even layer of lacquer. After drying, they are polished and recoated multiple times.

Lacquer processing scene : Frames (lined up on the right) have an undercoat and are coated with a thin, even layer of lacquer. After drying, they are polished and recoated multiple times.

As we continued to sell these clocks as long-life designs, new challenges arose. Initially, the central part of the frames was carved out to highlight the beauty of the turned wood. However, as production volumes increased, we switched to hollowing out the central clock face to improve efficiency, which resulted in offcuts. Although these offcuts were considered to be waste, they were still high-quality pieces of zelkova wood, just like the ‘MIKI’ frames. It felt wasteful to burn them as fuel, so we sought ways to repurpose them as per Lemnos’s unique initiative.

Offcuts from the center of the ‘MIKI’ clock

Offcuts from the center of the ‘MIKI’ clock

In 2012, when the ‘MIKI’ clock was released, the ‘MUKU desk clock,’ which was developed using walnut offcuts, was also available. When the product that originally provided the walnut offcuts was discontinued, the offcuts were no longer available. As a result, the wood used for the ‘MUKU desk clock’ was changed from walnut to beech and alder. Nevertheless, ‘MUKU’ remains one of Lemnos’ most popular products and continues to be sold today. Inspired by this success, we explored the possibility of repurposing the offcuts of ‘MIKI’ and visited the wooden frame manufacturing factory. There, we learned that their CNC machines required the material to be in a square shape for processing, which meant the cylindrical offcuts were unsuitable for use.

Product: MUKU desk clock/Walnut (LC12-05 WN – Discontinued)

Product: MUKU desk clock/Walnut (LC12-05 WN – Discontinued)

Returning to the skilled woodturners of ‘MIKI,’ we discovered that while they could easily shape the round front surface of the ‘MUKU desk clock,’ they did not have CNC machines, which were needed to process the rounded rectangular cavity on the back for the movement. Just as we were about to give up on the idea, the craftsman proposed a new jig design and hand-assembled a custom tool to take on the challenge of processing the offcuts. After numerous meetings and prototypes, we were finally able to have the ‘MUKU desk clock’ produced in the same shape using zelkova offcuts. In this way, the challenge of effectively utilizing the waste material was overcome.

Processing scene of the LC12-05 frames: Rounding the corners on the back.

Processing scene of the LC12-05 frames: Rounding the corners on the back.

Shaping the rounded rectangle cavity on the back for the movement. The board is designed to be movable, with a jig on its underside that restricts its range of motion.

Shaping the rounded rectangle cavity on the back for the movement. The board is designed to be movable, with a jig on its underside that restricts its range of motion.

Back of the LC12-05 zelkova frame

Back of the LC12-05 zelkova frame

There are various wood grain patterns.

There are various wood grain patterns.

Product: MUKU desk clock/Zelkova (LC12-05 KY)

Product: MUKU desk clock/Zelkova (LC12-05 KY)

As the supply continues to diminish each year, wood will become an increasingly precious resource. We aim to use materials more carefully than ever before, thus minimizing waste and maximizing their potential. The creation of the ‘MIKI URUSHI’ and ‘MUKU desk clock Zelkova’ was made possible through the collaboration of designers, skilled woodturners, and lacquer craftsmen. These products embody Lemnos’ commitment to balancing environmental sustainability with thoughtful design.