Sustainability

Lemnos Sustainability 09

JAL Boeing 777 Upcycling Project

The Creation Story of Clocks Made from Cabin Windows

Takata Lemnos continuously develops products while exploring new materials and technologies. In recent years, we have been focusing on utilizing recycled materials and components from a sustainability perspective. Based on this philosophy, we have been actively seeking partnerships with companies that share similar values. Among these efforts, we received a proposal from JALUX Inc., a trading company of the JAL Group, to develop products using recycled parts from retired and dismantled JAL Boeing 777 aircraft.

In this article, we are excited to introduce this initiative.

JAL Original Boeing 777 Cabin Window Wall Clock (White/Black)

JAL Original Boeing 777 Cabin Window Table Clock (White/Black)

JAL Group’s Upcycling Project

As part of a project planned by JALUX Inc., Takata Lemnos participated in the JAL Group’s aircraft upcycling project, overseeing the design and manufacturing of certain products. These products are original wall and table clocks that repurpose cabin windows from retired JAL Boeing 777 aircraft as clock face covers. They are available in limited quantities at JAL Shopping’s JAL Mall store.

〈 JAL Group’s Initiatives 〉

Through its “JAL Vision 2030″ initiative, the JAL Group aims to create a “safe and secure society” and a “sustainable future” by positioning ESG (Environmental, Social, and Governance) strategies at the core of its management approach. As part of this initiative, the JAL Group carried out Japan’s first recycling of a retired Boeing 777 aircraft in 2022. By fostering collaboration among its group companies and engaging with external partners, the JAL Group has successfully developed upcycled products using recycled aircraft parts.

〈 JALUX Inc. 〉

As a trading company within the JAL Group, JALUX primarily operates in the aviation and airport-related sectors. It operates the official Japan Airlines online shopping mall, “JAL Mall,” and the “JAL Furusato Tax Donation” platform. Additionally, JALUX manages “JAL PLAZA” stores at 24 airports nationwide.

The Story and Design of Aircraft

Although aircraft are a common sight, it’s hard to visualize the specific parts that make up these machines. Wanting to see it firsthand, we promptly visited the JAL Maintenance Center at Haneda Airport. There, we received explanations about dismantled aircraft parts and were guided through the hangars and facilities, including the JAL SKY MUSEUM, where aircraft are serviced. Seeing the process firsthand, we gained a deep appreciation for the meticulous work required to ensure the safe operation of aircraft. While newer aircraft models use composite materials made with carbon fiber to reduce weight, the Boeing 777 primarily relies on aluminum alloy. As Takata Lemnos frequently works with aluminum alloys in its products, we felt a natural affinity with this aircraft’s design.

Hangar at the JAL Maintenance Center

Hangar at the JAL Maintenance Center

Although products using recycled parts from retired aircraft have been available for some time, they are often targeted at collectors. For this project, however, the goal was to create aesthetically appealing products that would resonate with a wider audience. With this goal in mind, we explored various ideas for utilizing recycled parts. Ultimately, two concepts were selected: a wall clock featuring a face cover that preserves the cabin window’s original shape, and a table clock that uses a halved cabin window as its face cover.

JAL 777 Cabin Window

Proposal Image

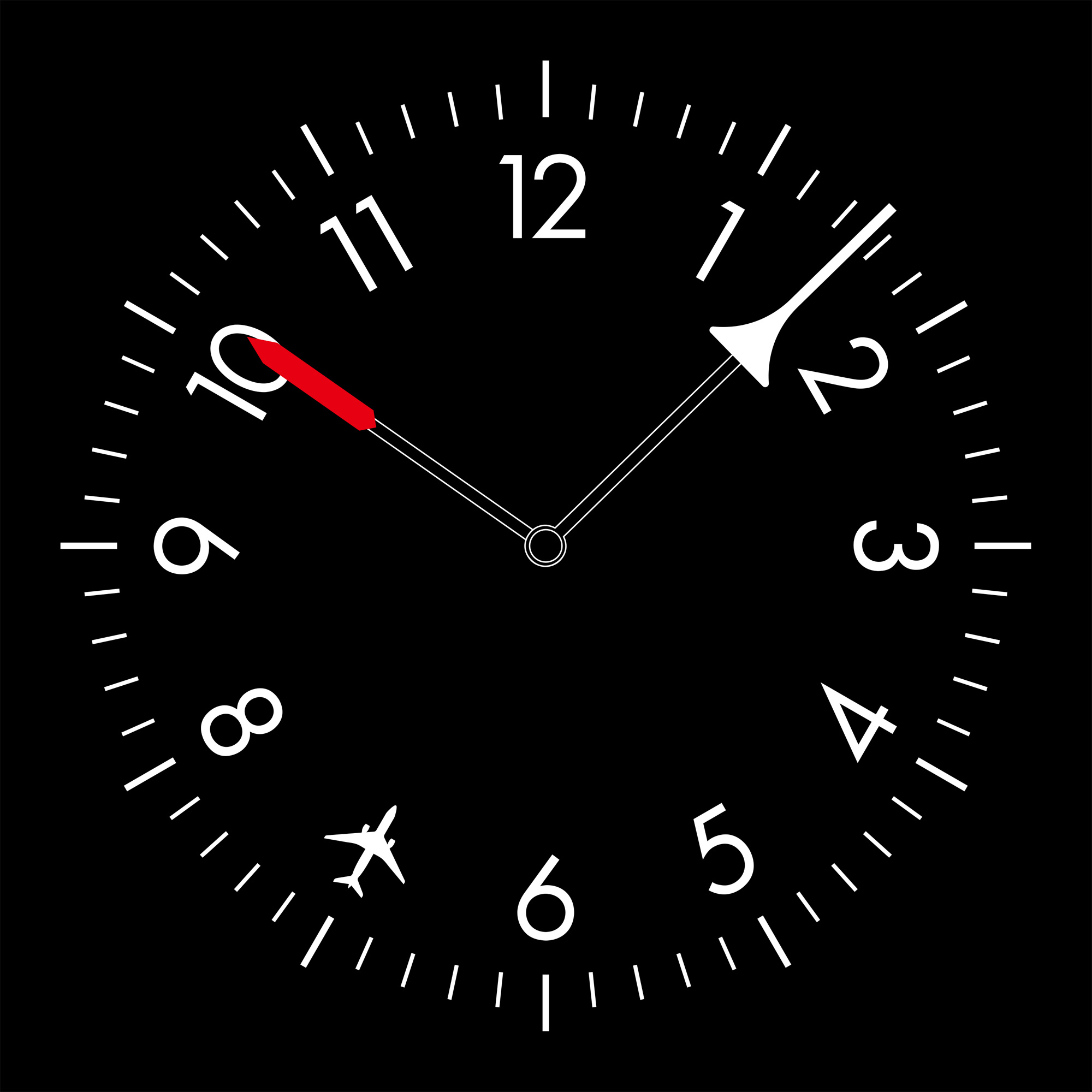

The clock design incorporates elements inspired by aircraft. The outer frame surrounding the face cover is crafted from a thin, curved steel plate, giving it a sleek appearance. It is coated in the same white paint used on the JAL Boeing 777 aircraft. The hour and minute hands, along with the markers, are inspired by cockpit instruments. While both instruments and clocks feature similar components, i.e., hands and markers, their concepts differ. Instruments are designed to optimize readability, enabling instant recognition of numerical values. On the other hand, clocks not only display the time but also convey relative durations, such as “20 minutes to 5:00.” This makes the spatial design of the dial, including the balance between hands and markers, a crucial element. By merging the distinct characteristics of instruments and clocks, the design achieves a perfect balance of readability and aesthetic appeal, resulting in a unique clock graphic.

Exhibit at the JAL SKY MUSEUM

Exhibit at the JAL SKY MUSEUM

Wall Clock Graphics

Wall Clock Graphics

Flexible processing leveraging the strengths of our partner factories

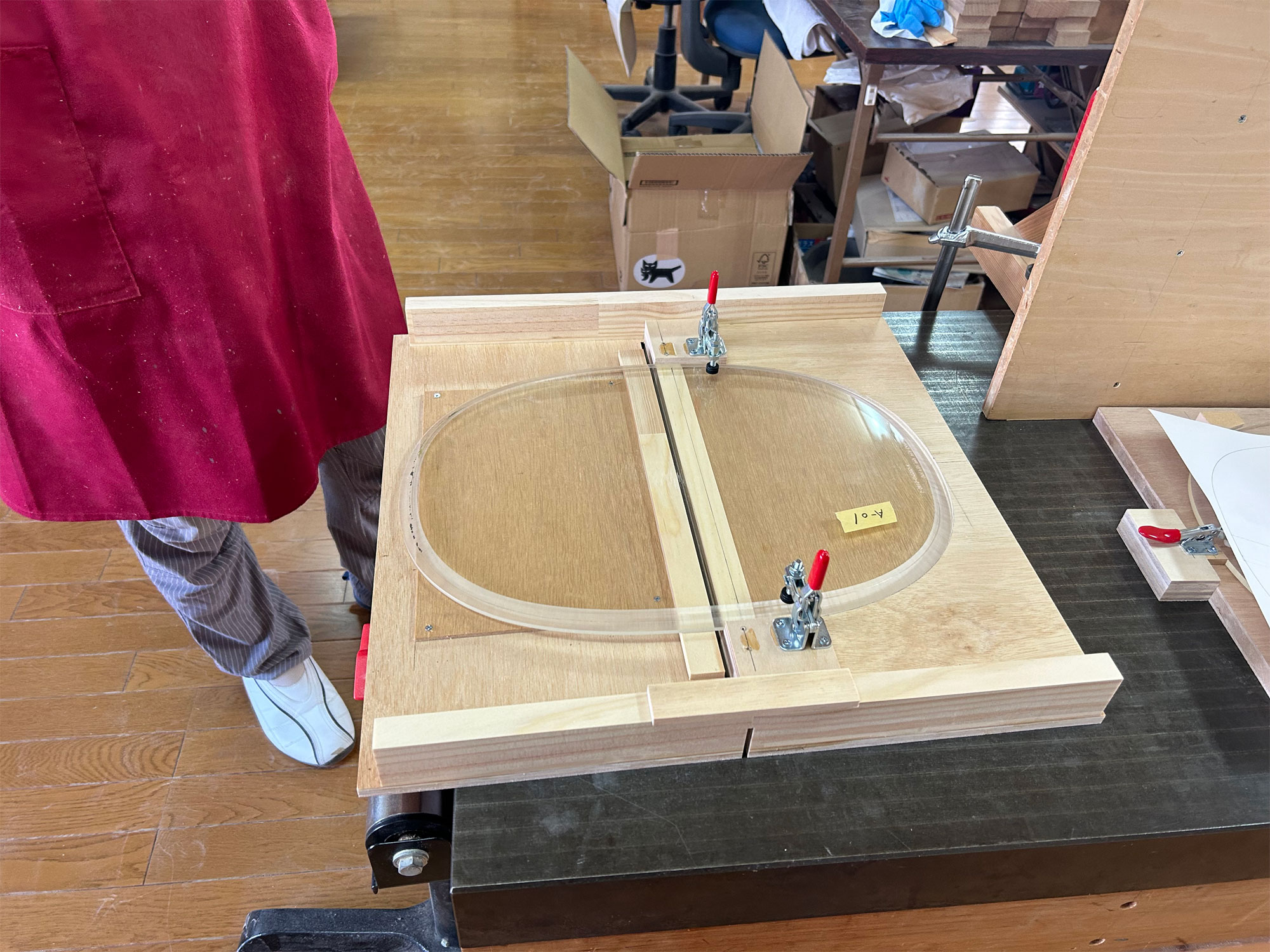

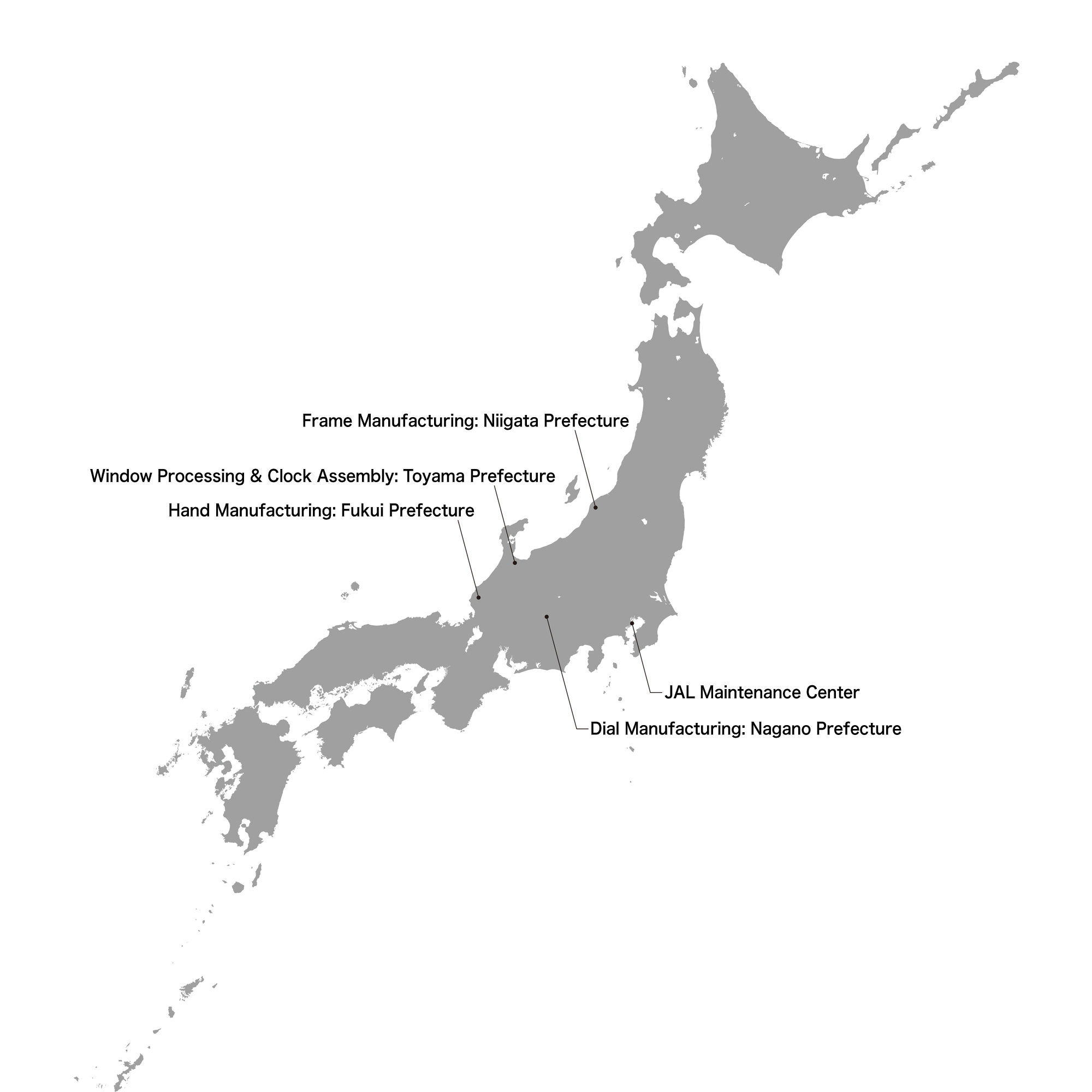

The processing of clock components was entrusted to partner factories across Japan, carefully selected to suit the specific characteristics of each material. The most delicate task was processing the cabin windows. These windows are made of two layers of acrylic panels with different thicknesses. However, unlike flat acrylic panels, they are curved to fit the aircraft’s exterior shape. Moreover, years of operation have left them with fine scratches, making each piece slightly unique. While flat acrylic panels can be precisely cut and drilled by machines, the irregular nature of the windows meant that each piece had to be inspected and processed individually by hand. To achieve this, a workshop in Takaoka City, Toyama Prefecture—specializing in wooden molds for metal casting—was commissioned to create custom tools specifically for processing the cabin windows.

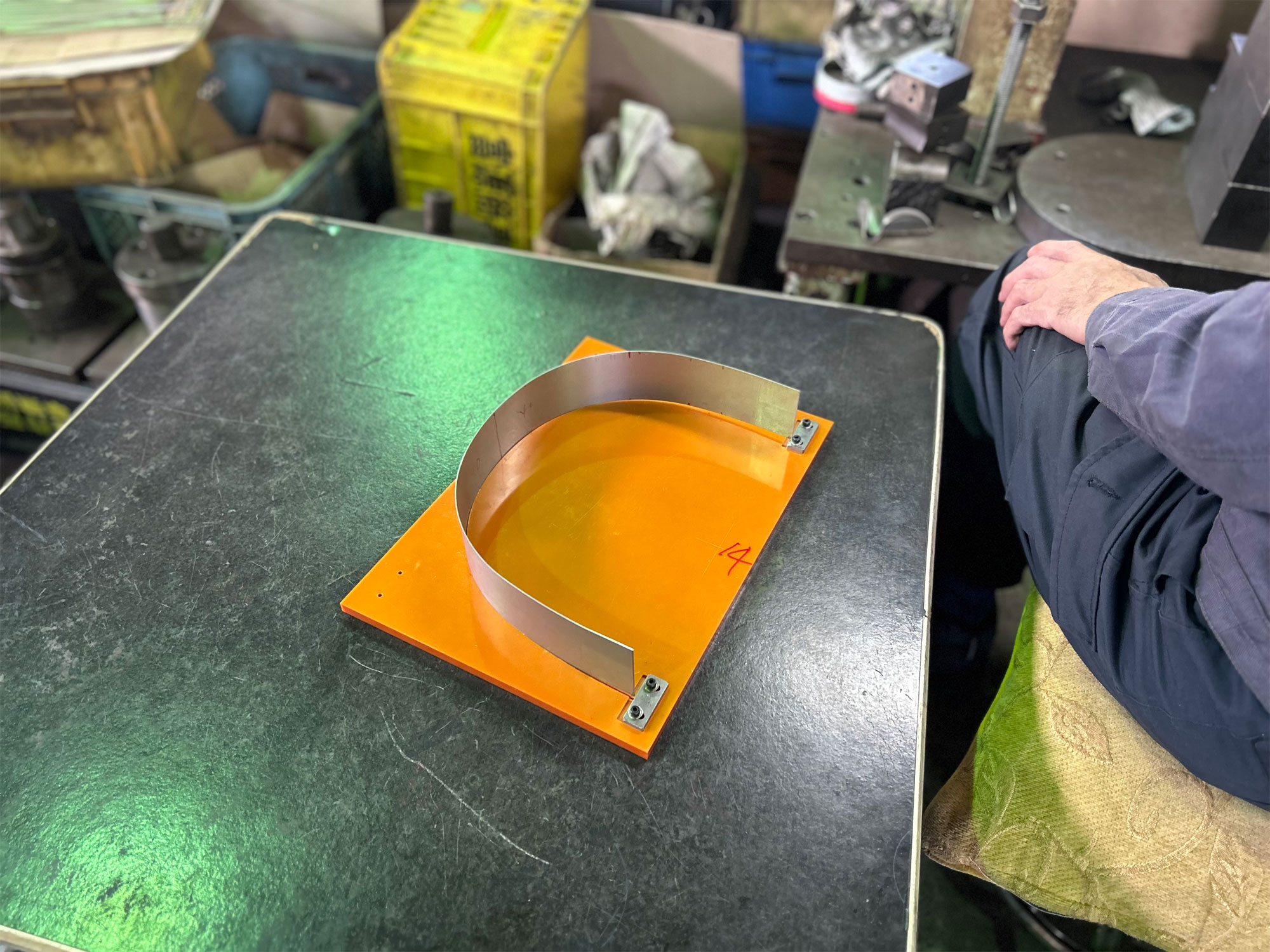

The outer frames, made by bending steel plates, were manufactured in the Tsubame-Sanjo area of Niigata Prefecture, renowned for its expertise in metal working. Skilled craftsmen carefully adjusted the bends one by one, using simple tools to ensure precision. The clock faces were crafted at a woodworking factory in Nagano Prefecture, while the hands were produced at a metalworking factory in Fukui Prefecture, known for its expertise in eyewear manufacturing. By leveraging the manufacturing hub of the Hokuriku-Shin-etsu region, centered around Toyama Prefecture where Takata Lemnos is headquartered, this clock came to life through collaboration with Japan’s finest artisans.

When using recycled parts, greater technical expertise and creativity are required compared to working with new materials. At Takata Lemnos, we have long applied our expertise in transforming designers’ imaginative concepts into reality. This manufacturing flexibility allows us to develop products with unique stories, distinct from mass-produced items. Moving forward, we aim to continue collaborating with individuals and organizations that share similar values and philosophies of craftsmanship.

The scratches on the cabin windows evoke a sense of history.

The scratches on the cabin windows evoke a sense of history.

We have preserved the original serial numbers and markings on the cabin windows.

We have preserved the original serial numbers and markings on the cabin windows.

A nameplate featuring the Japan Airlines logo and an engraved serial number is affixed to the back of the product.

A nameplate featuring the Japan Airlines logo and an engraved serial number is affixed to the back of the product.